ADVANTAGES

Glossy finish.

Creates a surface that prevents the formation of microorganisms.

Easy to clean and creates a sterile environment.

High tensile strength.

Superior chemical resistance compared to conventional epoxy coatings.

Easy to apply by brush, roller or spray method.

Waterproof.

Solvent-free.

APPLICATIONS

Used as a protective layer inside concrete tanks containing drinking water, some chemicals, oils and fuels.

As a waterproof, elastic and chemical-resistant floor or wall coating in food factories, breweries, canneries and bottling plants.

As a gas and vapor barrier coating, with chemical resistance.

As a protective and decorative coating in laboratories, slaughterhouses, etc.

Other areas of use include refineries, paper mills, power stations, garages, hospitals, sugar refineries, warehouses and most other liquid storage areas.

INSTRUCTIONS FOR USE

Surface preparation:

Concrete:

The concrete surface must be sound and have a minimum compressive strength of 25 N/mm2.

The surface must be clean, dry and free from contaminants such as dust, oil, grease, old coatings and surface treatment compounds.

Weak concrete and dust must be removed. Surface defects such as pores, voids, cracks and bumps must be treated and smoothed.

Steel:

The concrete surface must be sound and have a minimum compressive strength of 25 N/mm2.

In case the surface is immersed in chemicals, it is required to use a sandblasting machine to remove the peeling and contaminated components (rust, scale…) to ensure that at least 95% of the surface area is well controlled.

In case the surface is not immersed in chemicals, it is necessary to remove all rust, scale or foreign objects (the surface must be maintained in gray color); cleaning tools must be as specified and recommended.

Coating for all cases with metal surfaces must be deployed within 4 hours and without delay after the surface is prepared.

Check moisture and apply primer (when necessary):

Check surface moisture, relative humidity, dew point before application.

If the surface moisture is < 5%, it is recommended to apply an additional layer of epoxy primer LỘS Primer FS.

If the surface moisture is >= 5%, an additional layer of LỘS Primer MB moisture-resistant epoxy primer should be applied.

Check the moisture content and apply the primer (if necessary):

Check the surface moisture, relative humidity, dew point before application.

If the surface moisture is < 5%, an additional layer of LỘS Primer FS epoxy primer should be applied.

If the surface moisture is >= 5%, an additional layer of LỘS Primer MB moisture-resistant epoxy primer should be applied.

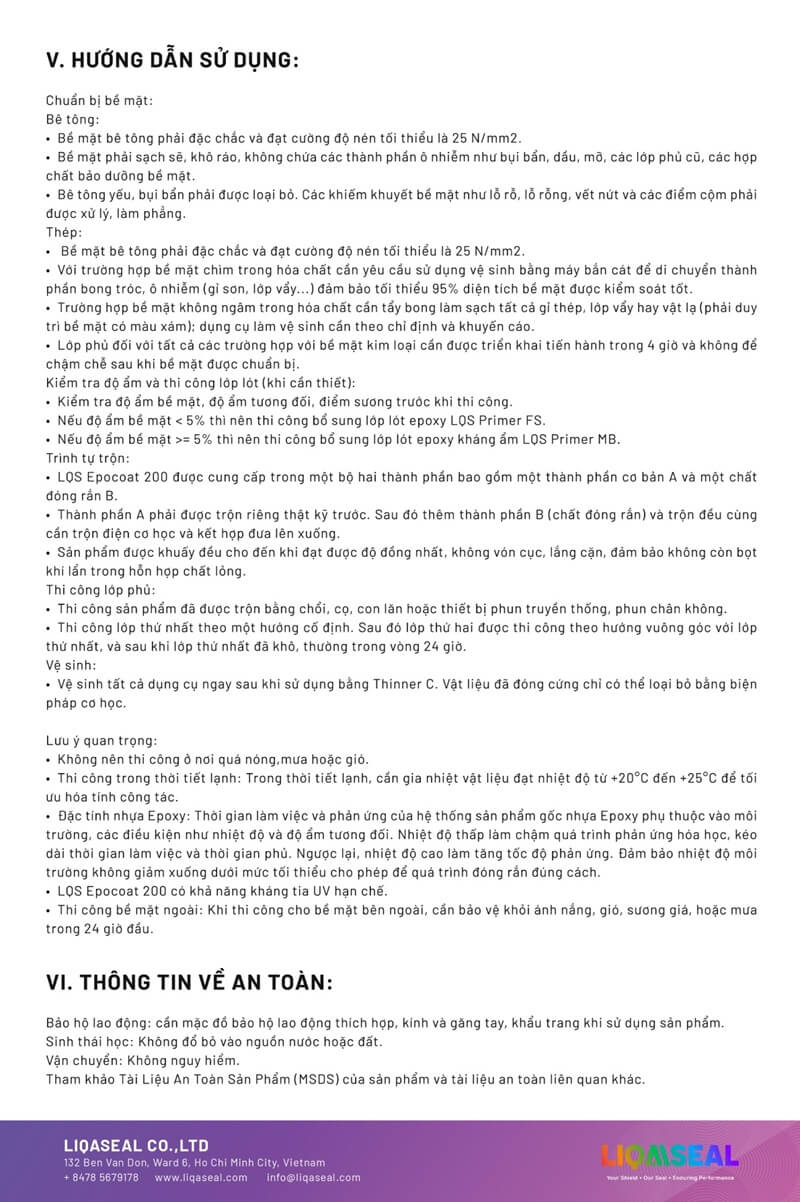

Mixing sequence:

LQS Epocoat 200 is supplied in a two-component kit consisting of a base component A and a hardener B.

Component A must be mixed thoroughly separately first. Then add component B (hardener) and mix well with an electromechanical mixer and combine up and down.

The product is stirred until a homogeneous consistency is achieved, without lumps or sediments, ensuring that there are no air bubbles in the liquid mixture.

Coating application:

Apply the mixed product by brush, brush, roller or conventional spray equipment, vacuum spray.

Apply the first coat in a fixed direction. Then the second coat is applied perpendicular to the first coat, and after the first coat has dried, usually within 24 hours.

Cleaning:

Clean all tools immediately after use with Thinner c. Hardened material can only be removed by mechanical means.

Important note:

Do not apply in places that are too hot, rainy or windy.

Application in cold weather: In cold weather, it is necessary to heat the material to a temperature of +20°C to +25°C to optimize workability.

Epoxy Resin Properties: The working time and reaction time of Epoxy resin based product systems are dependent on the environment, conditions such as temperature and relative humidity. Low temperatures slow down the chemical reaction process, prolonging the working time and coating time. Conversely, high temperatures increase the reaction rate. Ensure that the ambient temperature does not fall below the minimum allowable level for proper curing.

LQS Epocoat 200 has limited UV resistance.

Exterior application: When applying to exterior surfaces, protect from sunlight, wind, frost, or rain for the first 24 hours.

SAFETY INFORMATION:

Work protection: Wear appropriate protective clothing, goggles and gloves, and a face mask when using the product.

Ecology: Do not dispose of into water or soil.

Transportation: Not hazardous.

Refer to the product’s Material Safety Data Sheet (MSDS) and other relevant safety documentation.

Rating LQS EPOCOAT 200 – High performance epoxy coating, solvent-free, non-toxic